Categories

UML-05 PO RGB

Local Controller UML-05 PO RGB

The UML-05 PO RGB device is designed for the automation of belt and scraper conveyors. It controls and monitors the operation of a single conveyor or a chain of conveyors. Through the transmission bus, it is possible to monitor the operation of the conveyor or conveyor system and change the system operating parameters from a designated position of an authorized dispatcher.

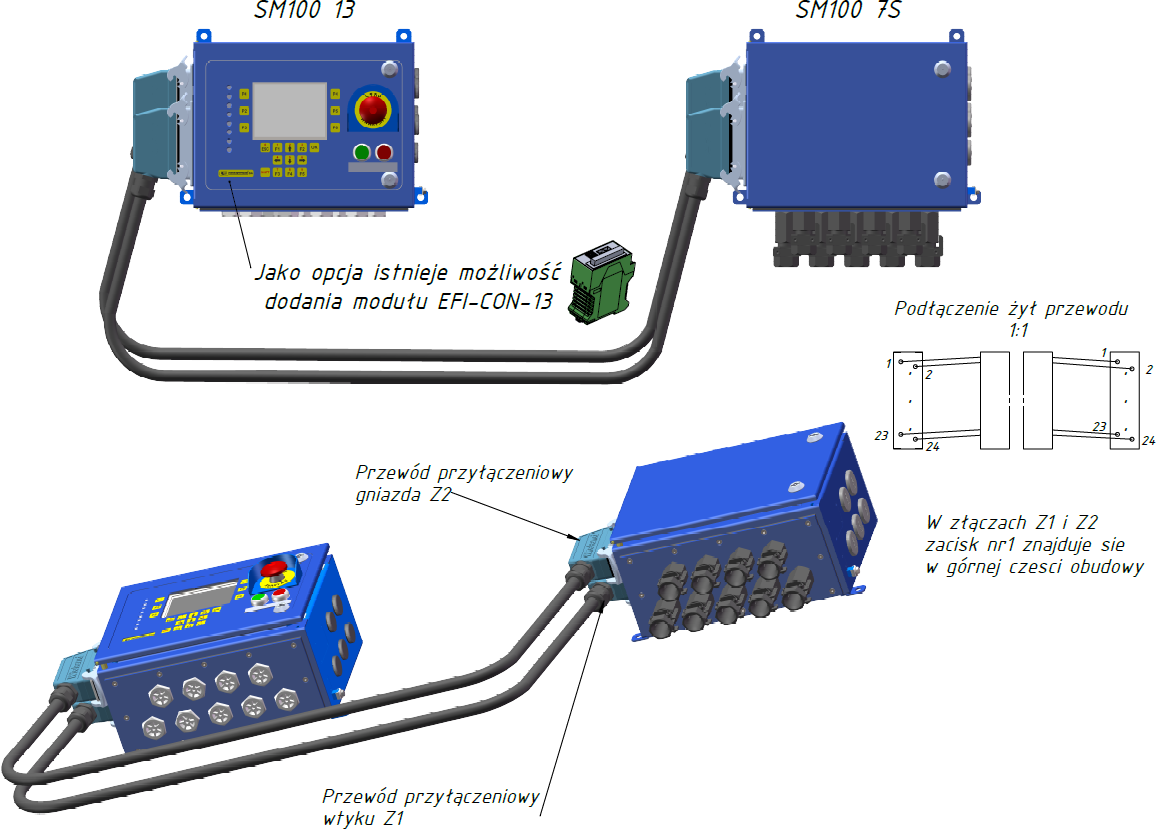

This is a UML-05 RGB type controller in which the upper chamber with electronics and the lower connection chamber have been separated. The chambers are connected by means of a dedicated cable on quick connectors. The upper chamber is installed in an optimal place for the personnel operating the conveyor, while the lower chamber is mounted in an optimal place from the point of view of electrical connections with sensors and other cooperating devices.

The device can operate in the ELSAP-05 system, which may include the following devices:

- Microprocessor Transmission Device type UMT-05

- Local Microprocessor Device type UML-05

- Local Microprocessor Device type UML-05/m

- Local Microprocessor Device type UML-05/o

- Local Microprocessor Device type UML-05/SZ

- Local Microprocessor Device type UML-05/PO

- UBL-05 type locking device

- SKD-06 Dynamic Crusher Controller

- UGS-10, UGS-01/2, UGS-01/1 or UGS-01 system,

- UGO-86 or UGO-86/1 and ISB-89 or ISB89/1 systems – for communication, hands-free, warning signalling and blocking

It has the following functional features:

- full compatibility with ELFAP-05 system drivers

- identical terminal strip as in the UML-05/P controller

- 5.6” graphic display instead of EM240 monochrome display

- identical programming menu as in UML-05/P

- the same information presented on each display screen, due to the large color display in a much clearer form

- identical work algorithm as in the UML-05/P controller

- viewing cameras with Ethernet interface connected to the controller or to the mining LAN

- synoptic board equipped with 8 colored LEDs with important functions assigned

- conveyor control in four modes - central control, local control, inspection work and people driving

- reading the status of binary sensors along with line control

- speed sensor support

- emitting warning signals and broadcasting verbal messages about the reason for the blockade

- control of a conveyor with various drive and brake configurations

- reading sensors connected to the UGS-10 system

- output control in the UGS-10 system

- reading and sending authorization signals for a chain of conveyors by voltage or via a transmission bus (LAP)

- control and full configuration via transmission bus (MODBUS protocol)

- display of all current parameters and locks on the graphic display

- archiving the reasons for blockages and changes in parameters

- taking over the function of the central controller in terms of switching on and off conveyor lines

Technical data UML-05 RGB version | |

Parameter name | Value (unit) |

Rated supply voltage | 12÷15VDC |

Maximum current consumption | 1400mA |

ATEX marking | I M1 Ex ia Ma I |

Ambient temperature range | - 20°C to +40°C |

Weight max. | 11kg |

External dimensions | 390x405x225mm |

Connection example