Categories

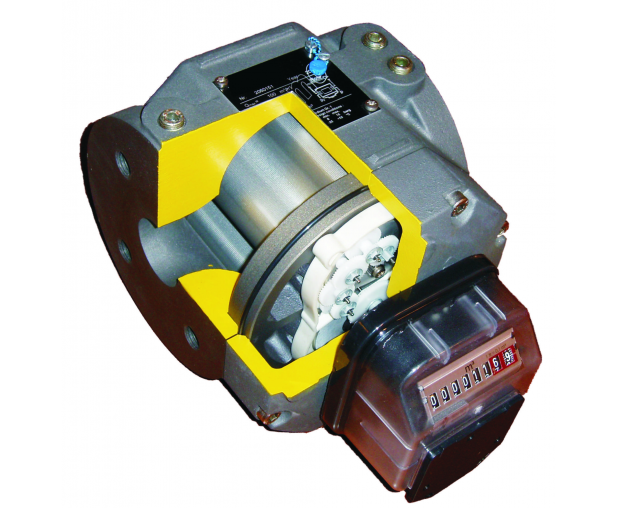

ROTARY GAS METER

Rotor gas meters are used in the gas-powered, chemical and furnace industries for the following gases:

- natural gas,

- city gas,

- propane,

- inert gases

The principle of operation of the rotary gas meter is well known. It is a type of positive displacement meter, feeding predetermined amounts of gas by means of two counter-rotating rotors. Four times for each revolution a fixed unit of volume is moved through the measuring chambers. The volume of gas flowing is proportional to the number of revolutions of the output device. The output device of this model of rotary gas meter is a specially designed magnetic clutch, one part of which is mounted inside the gas meter body, and the other part is located in the reading device. The reading device can be either a mechanical indicator or an electronic indicator with or without volume conversion and communication functions.

Advantages:

- reduced production costs, which is reflected in the product price

- reduced weight of the gas meter

- reduced overall dimensions, which allows the construction of compact measuring stations

- reduced pressure drop due to the typical shape of the rotors

- reduced Total Cost of Ownership (TCO) due to reduced maintenance costs

- reduced sensitivity to stresses in the installation thanks to the strong construction of the gas meter body

- reduced sensitivity to overload, gas contamination and pressure surges thanks to the robust design of the gas meter

- the gas meter is suitable for installation in accordance with local directives and quality levels while maintaining the highest reliability, performance and accuracy.

Nominal pressures | according to PN 10/16 and ANSI 150 | |

High pressure version | in progress | |

Collars | DIN, ANSI, JIS and others (on request) | |

Nominal diameters | From 1½” to 6” (DN 40 – DN 150) | |

Measurement range | Minimum 160:1 or better in atmospheric conditions. (European Union Standard – 1:20.) | |

Flow rates | From 0.5 m 3 /hour to 1,000 m 3 /time. | |

Repeatability | 0.1% | |

Measurement accuracy | From Qmin to 0.2 Qmax | ±2% or better |

From 0.2 Qmax to Qmax | ±1% or better | |

Temperature range | Standard | from -25°C to +60°C |

On request | from -40°C to +80°C | |

G rating | Size | Nominal capacity Qmax m 3 /time | Range | 2 x low frequency pulse (1 pulse per m3) | |

whole | mm | ||||

G 16 | 2" | 50 | 25 | 1:50 | n/a |

G 25 | 2" | 50 | 40 | 1:80 | n/a |

G 40 | 2" | 50 | 65 | 1:100 | 10 |

G 65 | 2" | 50 | 100 | 1:160 | 10 |

G 100 | 3" | 80 | 160 | 1:160 | 1 |

G 160T | 3" | 80 | 250 | 1:160 | 1 |

G 160 | 3" | 80 | 250 | 1:160 | 1 |

G250 | 4" | 100 | 400 | 1:160 | 1 |

G 400T | 4" | 100 | 650 | 1:160 | 1 |

G 400T | 6" | 150 | 650 | 1:160 | 1 |

G650T | 6" | 150 | 1000 | 1:160 | 1 |

G rating | Number of screws | Size | Overall dimensions from collar to collar | Height and depth | Total weight in kg Approximate values | ||

whole | mm | in mm | in mm | ||||

G 16 | 4 | 2" | 50 | 171 | 180 | 220 | 10 |

G 25 | 4 | 2" | 50 | 171 | 180 | 220 | 10 |

G 40 | 4 | 2" | 50 | 171 | 180 | 220 | 10 |

G 65 | 4 | 2" | 50 | 171 | 180 | 220 | 10 |

G 100 | 4/8 | 3" | 80 | 171 | 200 | 280 | 13 |

G 160T | 4/8 | 3" | 80 | 171 | 200 | 350 | 21 |

G 160 | 4/8 | 3" | 80 | 241 | 225 | 315 | 27 |

G250 | 8 | 4" | 100 | 241 | 225 | 400 | 30 |

G 400T | 8 | 4" | 100 | 241 | 225 | 510 | 43 |

G 400T | 8 | 6" | 150 | 241 | 285 | 510 | 50 |

G650T | 8 | 6" | 150 | 241 | 285 | 680 | 61 |